Choosing the right technology for your bakery!

In the world of bakery production, two major technologies stand out: batch mixing and continuous mixing. Each technology has its unique characteristics and advantages, catering to the different needs and preferences of manufacturers. But what sets them apart, and how do you decide which one is best for your bakery?

Discover in detail these two technologies!

Understand the basics!

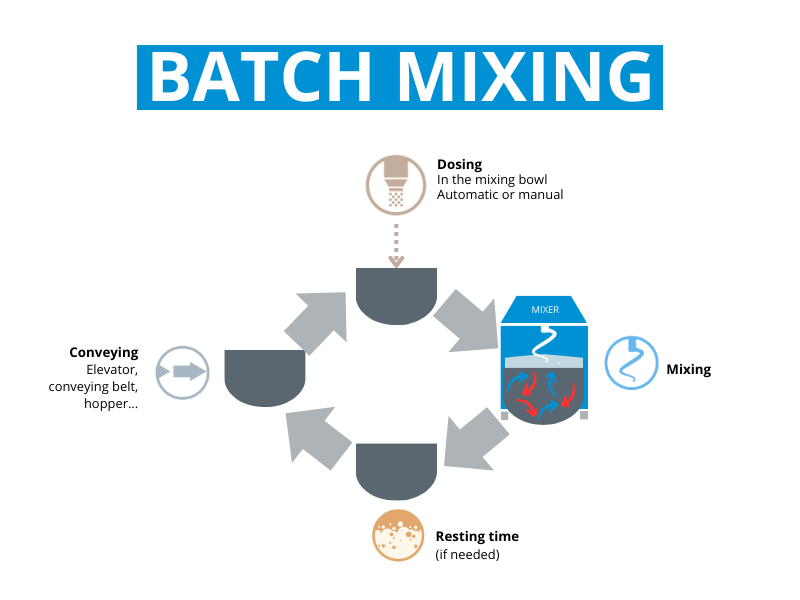

Batch Mixing: This method is the most common among bakery manufacturers. Mixing is done in a defined quantity each time, resulting in different batches. Once the ingredients are introduced into the mixing bowl, they are mixed until a homogeneous dough is formed. Then, the dough is discharged and transferred onto a conveyor belt or into a hopper, continuing its journey along the production line. Meanwhile, the mixing bowl is refilled with ingredients, either manually or automatically through a dosing station, and the process repeats.

There are various equipment operating with batch technology. In the VMI range, for example, we can mention vertical mixers such as the Kneadster or the SPI AV spiral mixer, both of which can be integrated into an automated system.

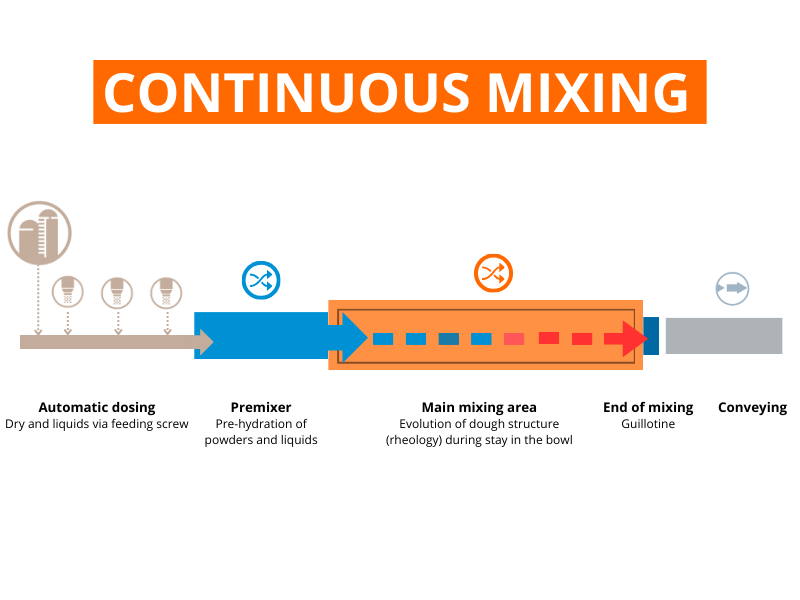

Continuous Mixing: In a continuous mixing system, ingredient dosing is automatic, and they are continuously fed into the mixing bowl. The use of a pre-mixer for the mixing phase allows for effective and rapid pre-hydration of powders and liquids. Then, the mixture enters the main mixing bowl for the kneading phase, and the dough exits smoothly, cut into dough pieces by a guillotine. It can then continue its journey towards a shaping line, rolling line, etc.

VMI is one of the most experienced manufacturers in continuous kneading. Its range includes: the Verymix and the Continuum.

Batch or continuous: a choice determined by the end product?

The application has a major impact on the choice of mixing technology. However, there isn’t one single universal answer. Many bakery products can be efficiently produced in both batch and continuous processes. The decision will depend on the customer’s process, product requirements and priorities.

Continuous systems are often preferred for the production of products such as cold, raw or par-baked doughs like bread or Viennese pastries.This is the case with our Verymix mixer.

The Continuum vacuum mixer is ideal for making soft products. Target products include soft bread or buns. This is made possible by the use of vacuum. Thanks to the design of its tool and bowl, the Continuum can be used effectively for a wide range of applications. These include the production of unstructured doughs such as cookies or biscuits.

Despite the versatility of continuous kneading, the batch system, with its versatility and ability to produce a wide range of products, including unstructured doughs, remains a popular choice in many bakery production contexts.

The decision will depend on the customer’s process, product requirements and priorities. In reality, it is often criteria such as production rate, volume to be produced, number of references and major changes to be made in the production process that will primarily guide the decision. It will be up to the supplier to advise the manufacturer towards the most suitable solution according to their needs.

What are the differences between batch and continuous technology?

Although the two technologies can produce similar products, each has its own distinctive strengths, often making them suitable for specific contexts or particular requirements.

The key strength of batch systems lies in their flexibility. Batch mixing offers great versatility, allowing easy adjustments between different recipes. This flexibility is particularly beneficial for bakeries producing a diverse range of products.

On the other hand, continuous systems are particularly well suited to ensuring high consistency and consistent product quality. This makes them an ideal choice for single-product production, or with a few key recipes produced in large volumes.

This consistency is ensured in particular by the level of automation of the continuous mixer. Indeed, each ingredient has its own dosing unit. All dosing is automated, limiting the risk of errors or deviations from the recipe.

For batch mixing, the level of automation is more variable, depending on the customer’s configuration, requirements and budget. If the process is manual there may be a risk of errors in dosing or in executing the recipe.

As for production volume and productivity in general, both technologies can offer a very high level of productivity (up to 8t/h in both cases, in fully automated configuration). However, batch kneading is better suited to diversified or medium-to-small-scale production.

Continuous mixing, with its smooth, constant operation, is preferred for large-scale production with few product changes, ensuring regular output with minimal interruptions.

Batch or continuous: choose the right technology!

Following this comparison of the two mixing technologies, certain trends and differences emerge. Let’s take a look at the factors involved in choosing the best option for your production.

Process factors

- Consistency and constant quality: For manufacturers who prioritize consistent quality throughout their production, continuous mixing offers a reliable and efficient solution, particularly for single-product production lines.

- Precise dosing: Continuous mixers are equipped with dedicated dosing units, controlled by weight sensors for each ingredient, ensuring automatic and precise dosing. This considerably reduces human intervention and minimizes the risk of errors. However, this precision has one drawback: it makes it difficult to modify recipes or add ingredients in small quantities, as this would require the installation of new dedicated dosing devices. Batch mixing, on the other hand, offers greater flexibility. It can be automated or carried out manually, which makes it easier to adjust recipes and add ingredients in small quantities without requiring major modifications to the installation.

- Volume and number of recipes: A continuous solution requires a minimum production volume (1.5 to 2T/h) to be relevant. Additionally, it is mainly optimized for a few key recipes with minimal major changes. Batch systems are more flexible, both in terms of production volumes and recipe changes.

- Temperature control: Some products require precise control of certain parameters, such as the temperature of the dough. Continuous mixers have a double jacket with glycol circulation. The shape of the bowl and the length of time the dough remains inside the mixing chamber means that the dough can be cooled very effectively to maintain a target temperature. The vast majority of batch mixers only limit the heating of the dough, they cannot cool it down.

- Atmospheric control: Vacuum kneading is ideal for obtaining soft products, as it allows you to control the texture of the crumb and the oxygenation of the dough. Continuous kneading is perfectly compatible with the use of vacuum, as it takes place in a completely closed and sealed mixing chamber. Although vacuum mixing is possible on batch systems, it can pose greater technical challenges to ensure a perfect seal and easy emptying and cleaning.

Factors linked to your organization

- Level of automation: Manual, semi-automated or fully automated production? Batch systems can offer different levels of automation, making them particularly adaptable to your needs. For example, with a semi-automated system, it is possible to add mixers to increase production capacity without having to make major investments or modifications to the line. This will be more complex if the system is fully automated with shuttles, for example. The continuous mixer is, by default, fully automated, from dosing to pre-mixing, mixing and emptying.

- Space and footprint: Assess the space available in your production facility. For the same production volume, continuous mixers generally have a smaller footprint than batch mixers, which can be advantageous for small spaces. However, this will depend on your recipe and the number of dosing units you require. The pre-mixer and mixer sections of a continuous mixer are compact, but this is not always the case for the dosing section.

- Getting started and support: Continuous kneading is less common than batch kneading, which can lead to reluctance among production teams accustomed to batch processes. The dough parameters and control differ between the two technologies. However, this factor should not hinder your decision. With the right training and support from the supplier, this technology can be integrated very easily. Often, just a few weeks of production are enough to convince the teams of its advantages and efficiency!

In summary, the choice between batch and continuous mixing depends above all on your specific needs and priorities. It is quite possible, for the same product and production volume, to offer two configurations, one batch and one continuous. While batch mixing offers flexibility and customisation, continuous mixing ensures consistency and efficiency, particularly for large-scale, single-product production.

VMI understands the diverse needs of bakery manufacturers and we offer a complete range of batch and continuous mixing solutions.

Whatever your needs, we have the technology to help you achieve your production objectives!

VMI supports you through its Process Development Centre. It’s the perfect place to design and test your products, using your raw materials and ingredients on our technology. 👇