Consumers are increasingly looking for baked goods that are good for their health. The nutritional quality of ingredients is becoming a significant criterion, as well as more digestible bread.

The use of sprouted grain in food products dates to ancient times and makes a comeback, providing a nutritional, balanced, and pleasurable answer for bread consumers. Germination transforms the grains, making them more digestible than dry grains. Sprouted wheat is very rich in minerals (Zinc, Calcium, Iron) and vitamins (B1, B2, B3…).

What are the specificities for mixing sprouted grain doughs?

There are several ways to mix sprouted grain doughs, depending on the equipment used and the desired result:

- Make a flourless dough by mixing sprouted grain with dried fruit, for example to make energy bars based on sprouted grain.

- Incorporate sprouted grain into existing bread dough. This has the advantage of increasing the enzymatic activity of the dough, providing more inclusions and taste.

- Dry the sprouts, grind them into flour and then use them to make the bread dough. For example, bakers can use sprouted rye instead of wheat flour.

A different texture from traditional dough

The texture varies greatly depending on the grain and the process. But sprouts give more softness and moisture to the dough. The solubility and digestibility of the proteins are greater and result in products of better nutritional quality. On the other hand, the proteins’ technological rates are slightly degraded. It is necessary to adapt the parameters of kneading, hydration, and shaping of the dough to obtain compliant finished products.

Three tips for optimal mixing of sprouted grain dough

Tip #1: Use the right mixing tool to successfully incorporate the grains into the dough (ground or not)

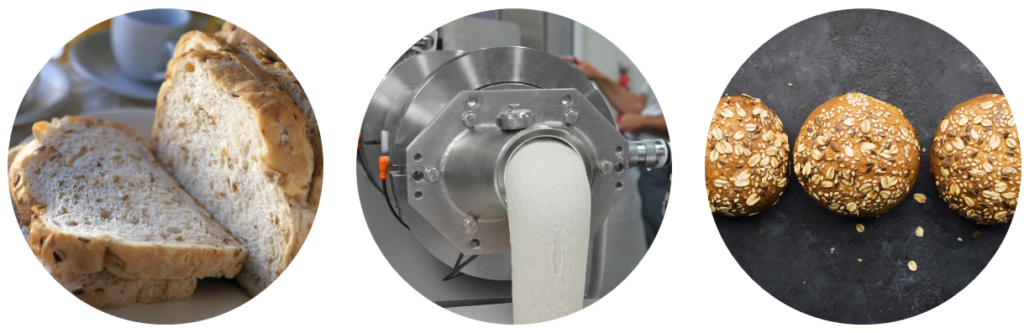

The equipment should provide a balanced ratio of shear, aeration, expansion, and dough compression during mixing. VMI’s KNEADSTER® mixer has been studied on different dough types to design the tool that will obtain the best results. Depending on the process, specific tools are available for mixing with whole sprouted grain. Bread dough tools are more suitable for mixing the dough with milled grains.

Tip #2: Identify and control the process parameters of the mixing process

As each sprouted grain has its specificity, the baker must identify the mixing parameters that will ensure the process’s repeatability. Here are some interesting actions to take to avoid over-kneading the dough, for example:

- Measuring and controlling the energy consumed during kneading

- Monitoring the temperature of the dough. Some mixers are equipped with a temperature sensor integrated into the bowl, with a real-time reading on the HMI.

- Use the recipe programming function: it allows you to record the recipe’s parameters and then launch the phases automatically. This mode guarantees the accuracy and repeatability of the recipe.

Tip #3: Include fermentation in the kneading process

Incorporating fermentation phases into the kneading process is also an excellent way to continue the enzymatic activity and preserve the dough’s texture and nutritional density. Again, having a process that is easily repeatable by programming or automating some of the fermentation and mixing steps is essential for industrial-scale production.

The points of vigilance to be known for the elaboration of dough with sprouted grain

The first point of vigilance is to have an impeccable hygiene during the handling of sprouted grain. It is essential to optimise the pre-treatment conditions to avoid health risks and cross-contamination. Here again, the choice of equipment helps to preserve a healthy environment by making it easy to clean: no retention area or visible screws, materials, cleaning system in place if possible.

A mistake regularly made is not to adapt the mixing equipment, especially the mixing tools to the process and the grains being processed, whose properties can vary greatly. The diameter and shape of the tools and their position in the bowl are decisive for successful mixing.

Finally, the importance of the pre-mixing, fermentation, and kneading phases in making the product and the desired characteristics should not be overlooked. The softness, the aeration, the acidity and aromatic compounds depend on the mixing phases, which are essential in the manufacture of sprout-based dough.

The importance of mixing technology in successful production

The continuous mixing process: the evolution of a technology towards more diversity in bakery product applications

Even today, the various known kneading parameters are not controlled by all the continuous mixers, sometimes coming from the plastic extrusion industry or having no capacity to control, regulate or monitor the entire process.

A wide variety of parameters can be modulated and combined to provide very different and customised products:

- Controlling the temperature and energy input to the dough to monitor and successfully develop the gluten network,

- Diversification of the mixing tools used,

- The separation of the premixing and mixing phases,

- Working on the surface of the dough in contact during mixing,

- Varying the vacuum or pressure levels.

For bread, for example, the mixing technology of the VERYMIX continuous mixer, from the VMI brand, integrates the fundamentals of kneading: premixing and then kneading, optimising the shape of the tool, controlling the energy and aeration of the dough.

The major innovation in recent years has been the introduction of vacuum in continuous kneading. The regulation of the atmosphere significantly increases the dough’s regularity and, above all, makes it possible to act on the structure of the crumb, to move towards the production of soft products such as buns or sandwich bread. The CONTINUUM®, a continuous vacuum kneader unique on the market, improves the dough’s elasticity, ensures a high energy transfer to the dough, and allows to obtain a crumb with finer and more regular bubbles resulting in softer slices.

The integration of liquid pre-ferments and sourdough into the continuous mixing technology

The addition of yeast and pre-ferments has increased the dough preparation phases and has undeniably made the mixing processes more complex. However, these ingredients’ benefits are pushing bakery manufacturers to modify their mixing processes: improvement of flavour, texture, and shelf life of the products. To carry out these processes in a repeatable manner, automation and process programming are key to a fermentation-based recipe’s success. Whether it is fermentation, proofing, degassing, the introduction of yeast or yeast: nothing is left to empiricism, and each recipe is carried out with precision.

The integration of phases ancillary to kneading with batch mixing technology

The use of buffer tanks for these fermentation stages, managed automatically by a supervision system, makes it possible to implement batch technology to obtain flexible and evolving processes. In the image below, an example of batch mixing technology implemented with automated management of premixing, fermentation, leavening, and kneading:

Batch technology allows a complex and lengthy mixing and fermentation process while maintaining high productivity of 15 to 16 bowls per hour.

Continuous mixing technology also allows this type of process to be integrated by separating the continuous phases of premixing, fermentation, and kneading. For example, VMI’s horizontal pre-mixer allows the first phase of homogenisation of the mixture. This mixture can then be integrated directly into the continuous mixer or be placed in buffer tanks for a fermentation phase, while other tanks feed the mixer. In the same way, continuous mixers allow for the automated management of flows toward resting phases or a transfer to the line while also reintegrating the dough scraps. Depending on the mixing stage, the shape of the tools and the bowl will vary according to the process’s step, from premixing to kneading or fermentation.

The impact of mixing technology and process parameters on the final product

Depending on the desired product, the mixer’s technology will have an impact on different aspects of the mixing process: shear, extension, compression, aeration, and energy transfer. The mechanisms involved will impact the texture of the final dough: stickiness, elasticity, firmness, extensibility.

For many years, VMI has been working on the kneading phenomenon to offer manufacturers more efficient processes. The ONIRIS University in France is currently using a prototype, which involves all the kneading parameters and whose variations are all recorded, traced, and analysed to further improve the equipment’s relevance.

Increasingly, VMI technologists are intervening on-site or in the VMI test and development laboratory to help manufacturers intervene in their processes. Line audits or training courses are valuable tools for improving the mixing phase. It is not uncommon that with a better implementation of kneading, the formulation is also adapted to move towards clean-label fermented products or better shelf life.