To be a baker is, above all, to be passionate. Although investing in one’s work should not lead to suffering, the food professions are often considered as very demanding. Several difficulties come to face this passion, sometimes putting an end to work.

Artisan bakers: what are the risks?

Several factors can explain the risks of the baker’s work:

- Physical factors: repetitive movements, excessive effort, extreme joint positions, carrying heavy loads, flour dust emissions, etc.

- Psychosocial factors: time pressure, lack of autonomy, lack of social support, repetitive work, noise pollution from bakery equipment.

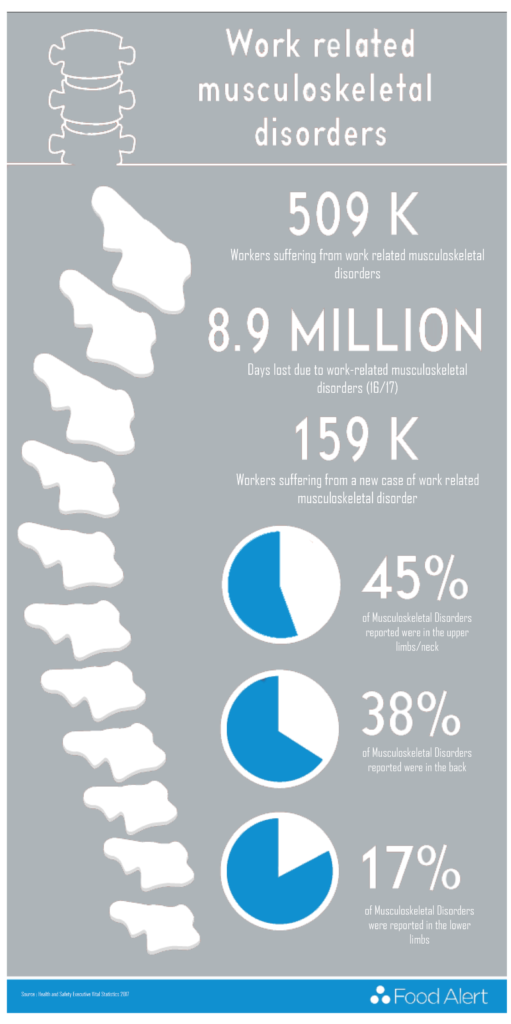

Musculoskeletal disorders (MSD) result from these difficulties linked to the workstation and the bakery environment. They can also come from the work environment or the company’s social climate.

How to prevent musculoskeletal disorders (MSD)?

Recognizing musculoskeletal disorders

MSDs are physical alterations that mainly affect soft tissues, i.e., muscles, tendons, or nerves. Carpal tunnel syndrome or tendinopathies are the most common disorders. The first pains usually appear in the back, shoulders, and elbows and should be taken seriously. Often expressed as pain, clumsiness, or loss of strength, MSDs can become irreversible, chronic, or cause lasting disability.

Preventing and avoiding MSDs

Prevention solutions can reduce the risk of MSDs and improve the quality of work for employees.

The prevention process is essential. Communicate as soon as the first pains are felt with colleagues and/or managers. Managers must react as soon as the first complaints are received.

The choice of equipment is also crucial to improve working comfort. Bakery kneaders and mixers are possible levers to reduce the daily workload of bakers and pastry chefs.

- A well-adjusted bowl height will allow avoiding bending over too much, whether for access to the tool or for emptying the bowl.

- Cleaning is a step that generates movement. The mobility of the machine must therefore be as easy as possible. Moving the bakery mixer easily allows for faster cleaning of the work area. Some mixers can be equipped with a removable castor kit at the front of the machine, which can be removed without having to bend down. A foot pedal is also convenient for handling a spiral mixer, whose weight with a full dough bowl can be 200 kg for the largest models.

- All the advantages of equipment that reduces excessive pushing or carrying of loads should be considered: integrated water inlet to reduce heavy loads and make the cleaning phase easier, assisted lifting of the mixer head for easy access to the spiral or to change the mixing tools, etc.

While reducing these repeated efforts is an essential area for improvement, nervous fatigue also plays a role in the working conditions. Comfort in the workplace can be improved by simple changes, which are underestimated daily.

- Continuous loud noise in the bakery or laboratory can damage hearing. It also causes stress and nervous fatigue. Machine guidelines require manufacturers of baking equipment not to exceed 75 dB. Some mixers or kneaders can run quietly, even for making hard, low-hydration doughs.

- The lighting of the bowl during kneading and mixing is an additional comfort. It improves the visibility and control of the baker’s production.

- An easy-to-use interface also plays an important role. The control screen is used to record the craftsman’s recipes, which are then executed and reproduced by the bakery or the laboratory employees. Who has not experienced the complexity of programming with an incomprehensible interface? Intuitive touch navigation, as we know it on smartphones, saves time!

Bakers are exposed to another occupational disease: baker’s asthma.

How to fight baker’s asthma?

Even less visible than MSD, baker’s asthma is the leading cause of occupational asthma in France, caused by flour dust. This respiratory disorder, characterized by inflammation of the bronchial tubes, causes breathing difficulties for bakers. In the bakery, they are continuously exposed to the flour and its irritating properties. Repeated exposure may cause tissue inflammation leading to allergic reactions and respiratory problems.

Recommendations and assistance to limit exposure to flour dust

In response to this difficulty, measures have been put in place by the bakery-pastry industry. In France, recommendations and assistance are provided by the Health Insurance and regional occupational health organizations. Concerning bakery equipment, the Machine Directive 2006/42/EC and European standards require that machines installed in a bakery or laboratory be equipped with a solid, sealed bowl cover. This is to protect against the emission of flour dust, which can cause allergies over time. Ingredient introduction hatches should close automatically to limit the escape of flour nanoparticles. In conjunction with the mobilization of the industry, VMI has adapted all its ranges of equipment.

The progressive mixing speeds when changing them prevent splashing, including flour dust emissions. Bakers now have an answer to the health risks involved. As an employer, the artisan baker is liable for his staff’s level of exposure to respiratory allergies.

Another initiative of the sector: the development of a flour dust index by the LEMPA (National French Bakery and Pastry Laboratory)

About ten years ago, a dedicated device started to quantify flour dust emissions in some retail bakeries. This instrumentation was placed in bakeries of different sizes to record the emissions during a production day. The standardized technique was applied to a hundred flour samples from about thirty flour mills with similar water contents.

Artisans are not exposed in the same way to flour dust depending on the origin of the commercial flours or the supplier. Commercial flours are very variable and can even be five times higher depending on the dust index:

- Less powdery flours (index to 4)

- More powdery flours (index to 20)

From one milling to another, the powdery index varies. Therefore, the LEMPA encourages the implementation of a method to measure the quality of flours.

The analysis of health risk factors for bakers and pastry chefs has allowed providing answers to protect their health better and strengthen their business performance. VMI places the user at the heart of its developments. Thanks to close collaboration with the entire industry and ongoing investments, the design of mixers and kneading machines for the bakery-pastry industry has been rethought to limit the risks of MSD and respiratory allergies as much as possible.