The constant increase in demand for baked goods is forcing manufacturers to rethink the organization of their production. Automation is a solution to increase efficiency and address current issues such as labor shortages.

However, the transition from manual to fully automated production raises a certain number of questions:

- Can you easily produce recipes that are technically demanding?

- Is it possible to implement complex manufacturing processes with flexibility?

- How are multiple recipes coordinated within the same system?

Rather than ushering in the end of authenticity for the sake of productivity, automated production lines provide bakers with an effective solution to produce high quality, distinctive products.

What is the biggest advantage of automated production lines? Each machine is designed to specifically meet the needs of each manufacturer. Read this article to find out why you should consider investing in automation for your bakery business.

Automation ensures consistent production while providing maximum process flexibility

What is an automated batch mixing system?

Automated mixing systems integrate a series of kneaders or planetary mixers, organize and automate the passage of the bowls from one station to another.

Automated mixing systems increase productivity. The order of the recipes is studied and optimized to limit waiting time and minimize non-production time.

For example, the VMI automated mixing system allows:

- Production from 1500 kg to 8 tons of dough/hour

- 24 hours a day, up to seven days a week

Integrated customer process parameters tailored to production needs

The modular design of automated systems allows you to select the mixing technology and line configuration in accordance with recipe and process requirements. Automated systems provide solutions tailored to the specific needs of each bakery or snack manufacturer:

- Required dough flow: The number and type of mixers (enabling more or less quick dough mixing ) and bowl capacity to be integrated into the system vary depending on the flow needed.

- Recipe type: Depending on the type of dough, the installation can integrate planetary mixers, batch mixers (with single or double tool) or fork mixers.

- Production rate: The type of recipe will determine how much passage time is required. Small batches are preferred if a quick production rate is required. As a result, there will be more mixers on the line. Larger batches are preferred if there is no time constraint allowing you to have fewer pieces of equipment on the line and optimize space.

Setup flexibility: tailor production steps to product needs

Depending on your product, you can adjust your process and integrate several phases into your installation:

- Dosing of ingredients

- Mixing phase: pre-mixing, mixing, kneading

- Resting phases: autolysis, resting

- Manual or automatic incorporation of ingredients, trimmings, fermented dough or liquid leaven

- Dough transfer and discharge

Automated systems are therefore suitable for both direct and indirect processes and allow integration of different phases of bread fermentation such as autolysis or resting. During these periods, the dough will develop thanks to the presence of yeast or sourdough and gain in volume and extensibility. The products made after a period of fermentation will have a more honeycombed crumb and better taste qualities.

Variety and complexity of recipes

Automated batch systems can be adapted to a wide range of recipes and all types of dough: pizza, pastries, bread, baguette, ciabatta, doughnuts, with the possibility of linking various recipes.

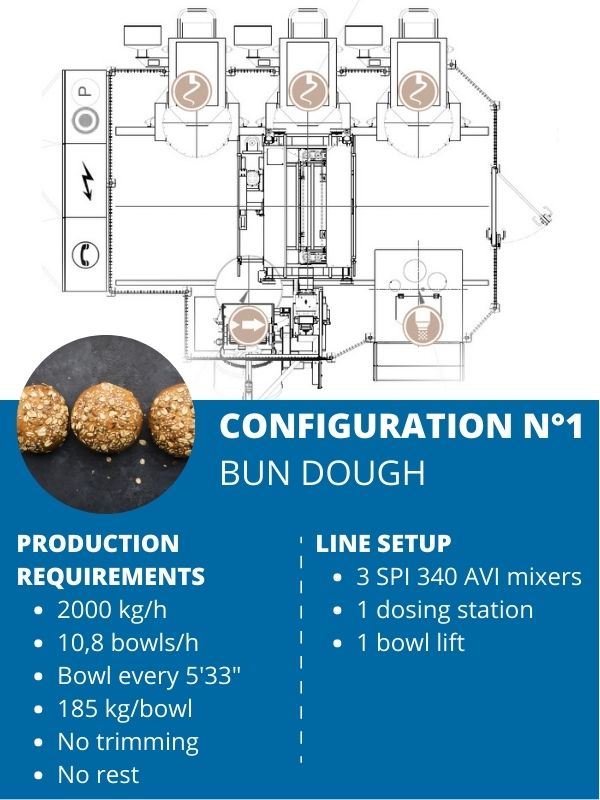

Bun dough: A configuration for dough that does not need to rise, with a fast pace and very little rest between kneading and dough transfer.

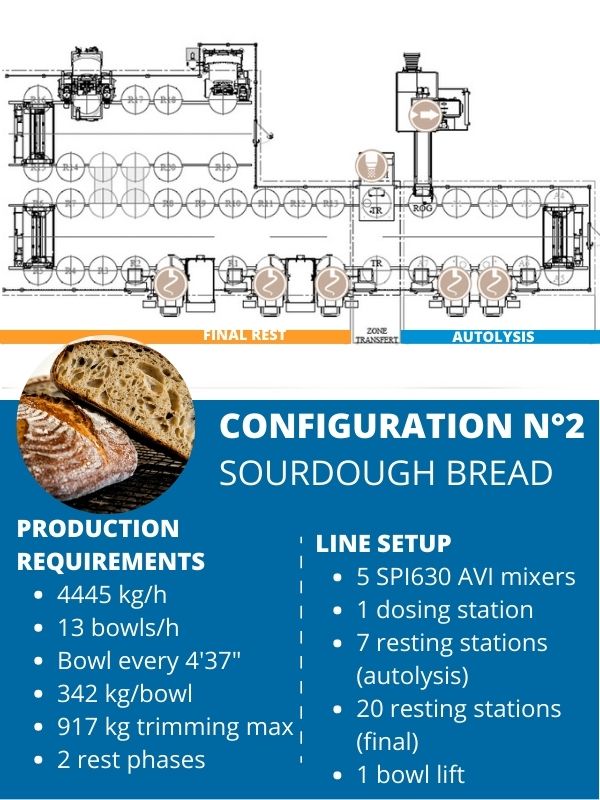

Sourdough bread: A configuration with several rest and fermentation phases.

A batch system can also manage several recipes simultaneously. Up to 3 production lines can be supplied. A large number of recipes can be saved and easily added to the production schedule. Each recipe process is customizable, allowing you to add or delete steps. Transitioning from one recipe to another couldn’t be easier.

Moreover, if the installation integrates a washing station, the bowls can be washed during or after production, which improves productivity and optimizes the flows. Bowls with allergens are clearly identified and it is possible to sequence different productions with peace of mind.

Automated production line: scalable, modular solutions

Automated mixing systems are modular and scalable to fit your requirements. The project allows you to choose from several configurations. You can weigh your options and make decisions based on your priorities such as speed, cleanliness, adaptability, installation area, and the degree of line automation.

You can choose each of these stations based on your needs with a high level of customization:

- Dosing can be done automatically via a dosing station or manually via a hatch. You can choose how each ingredient is incorporated, which allows you to incorporate inclusions (chocolate chips, dried fruits) at different stages of the mixture.

- Addition of a trimming station for automatic dosage of trimmings. This limits raw material loss and saves money.

- A wide range of shuttle technology to move the bowls around:

- Suspended or ground shuttle: the ground shuttle travels on rails that are attached to the ground and is therefore faster than the suspended shuttle. But, cleaning the production area is much easier with a suspended shuttle as nothing is on the floor. Therefore, it is the best option for recipes where compliance with hygienic standards is the major priority rather than speed.

- Single or double shuttle: The single shuttle can only pick up one bowl at a time while the double shuttle can pick up two: it picks up one tank at a station and simultaneously puts down another one on this same station, thereby limiting the movements within the carousel and enabling a higher rate. However, it is more cumbersome.

- Separate shuttles: They each have an assigned area as well as a common area (2 stations). This way it is possible to implement complex processes, with many rest phases while maintaining a high production rate. For example, one shuttle takes care of the first part of the process (dosing, frasing, kneading) and the second takes over (autolysis, kneading).

- Dough discharge station: Possibility to add one or more elevators to ensure dough discharge. This one can be done towards a hopper, a conveyor, a container…

- Cleaning station: The tank is automatically taken to the cleaning station where it is cleaned with a high pressure water jet. The cleaning station is particularly useful to avoid cross-contamination between several productions, especially in case of allergen presence.

Automation, a genuine advantage for manufacturers…

For bakers and food manufacturers, automation offers many advantages, including higher productivity, output uniformity, increased safety, and lower labour costs. Above all, automated systems can be specifically tailored to manufacturer requirements. For food and baked goods production facilities automation is a genuine advantage. Offering flexibility and customization, automation supports manufacturers as their production increases and expands.

The adaptability of automated systems allows you to preserve your recipes and skills, empowering you to create delicious, high quality traditional products while using complex processes.