The launch of a new product in the care and cosmetics industry is usually associated with five main steps:

- The identification of ingredients and raw materials

- Formulation development in the laboratory

- Objectivation: series of tests (in vitro, ex vivo, tolerance, clinical trials, consumer tests, etc.)

- The regulation: validate the conformity of the product and proceed to its registration. Depending on the country where the product is marketed, this stage can considerably extend the project’s duration.

- Distribution channel: importers, distributors, retailers, online sales etc.

However, a 6th crucial step should not be neglected: the process phase. This phase takes place between formulation and objectification. It includes determining of the elements that will allow the manufacturing of the product: equipment, the geometry of the mixing tools, process parameters (speed, time, temperature, vacuum), sterilization and cleaning data or extrapolation.

The process is an essential variable during the development of a new product because economic and safety issues depend on it:

- The finished product’s quality, to obtain the same result like the one elaborated at the laboratory scale.

- Safety for the operators in production and for the final consumer

- The marketing of the product

- Production yields: manufacturing time, energy, water, and detergent consumption

The main principles and challenges of the mixing process

Mixing is a unitary operation present in the transformation processes. It consists of bringing together several components to produce a homogeneous result. The procedure makes it possible to get the ingredients into contact and promote the transfer of heat, matter, quantity, and movement according to the application.

The operation provides mechanical energy, which increases the homogeneity and decreases the segregation of the mixture. Depending on the manufacturer’s homogeneity requirements, a successful mixture can be analysed according to:

- The uniform concentration of the mixture from any sample

- The specific segregation scale: homogeneous mixture at the macromolecular, nano-molecular, micro-molecular scale

- An optimal mixing time to calculate the required manufacturing time

The mechanical stirring system

A wide variety of mixing technologies exist. One of the most widespread is the mechanical stirring system (agitated tank). Consider five key parameters that impact the mixture:

- The tank: the dimensions and shape of the bottom of the tank

- Type and number of agitators

- The rotation of the mobile: speed, flow regime (laminar or turbulent)

- Duration of mixing

- The physical conditions imposed (pressure, vacuum, temperature)

The 5 steps to follow for a successful mixing

To obtain a good agitation, laboratories or industries must take different parameters into account:

- The nature of the product (liquid, powder, solubility) and its fluids’ rheology (viscosity).

- The technical dimension: stirring tool, peripheral speed, shear rate, etc

- The economic dimension: sector of activity, geographical location, consumption levels (energy, water, production time, etc.)

Step #1: identify the type of mixture to be made

The first step is to know the mixture’s nature to be made: is it a liquid/liquid, liquid/powder mixture? Are the liquids miscible or non-miscible?

Step #2: characterisation of the ingredients mixed

After identifying the type of mixture to be made, it is necessary to know the characteristics and rheology of the ingredients used: density, solubility, granulometry, viscosity, crystals, capsule, gas, etc.

Step #3: characterisation of the mixing tools

Good knowledge of the type of mixture and the ingredients involved makes it possible to determine the flow required for optimal mixing: radial, axial, rapid agitation, etc. The design and geometry of the tool vary the shear and flow levels.

Step #4: definition of the tools in a tank

The location of the tool(s) in the agitated tank affects the pumping and shear rate.

Step #5: calculation of mixing parameters

The definition of the previous steps allows calculating the mixing parameters: rotation speed, peripheral speed, circulation rate in the tank, mixing time.

Choosing the right mixing tool according to the application and mixing process

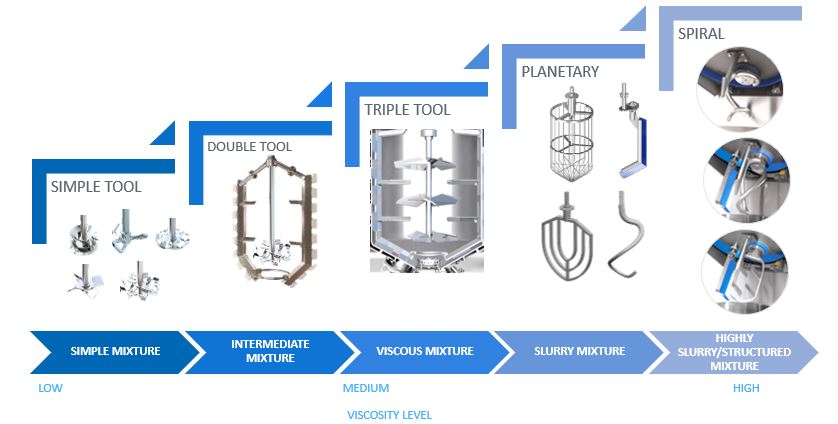

The determination of the tool will depend on the type of mixture. There are four main types of mixing familiar to any application sector.

How to choose the right tools for a liquid/liquid mixture with miscible liquids?

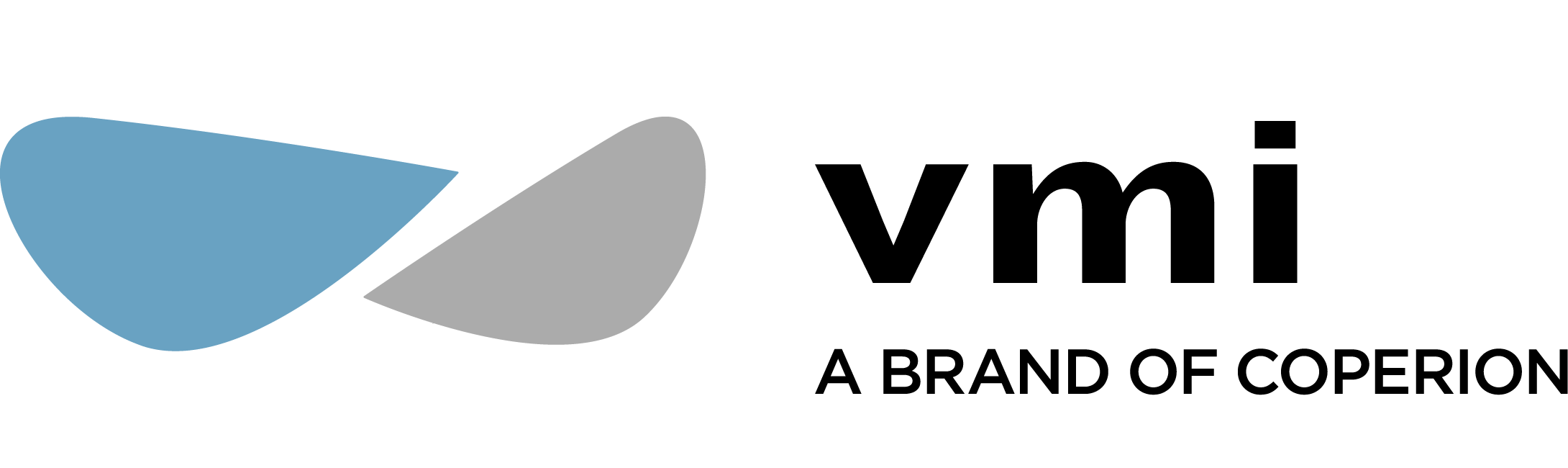

In a mixture of several miscible liquids, the operation must make it possible to dilute and homogenise the ingredients. To do this, the mixing mobile must generate a high pumping rate to promote circulation.

Axial flow propellers promote circulation in the medium. To homogenise the liquids and the temperature (heating/cooling), our experts recommend using turbines such as the four-blade, profiled three-blade, and marine propeller.

How to choose the right tools for a liquid/liquid mixture with non-miscible liquids?

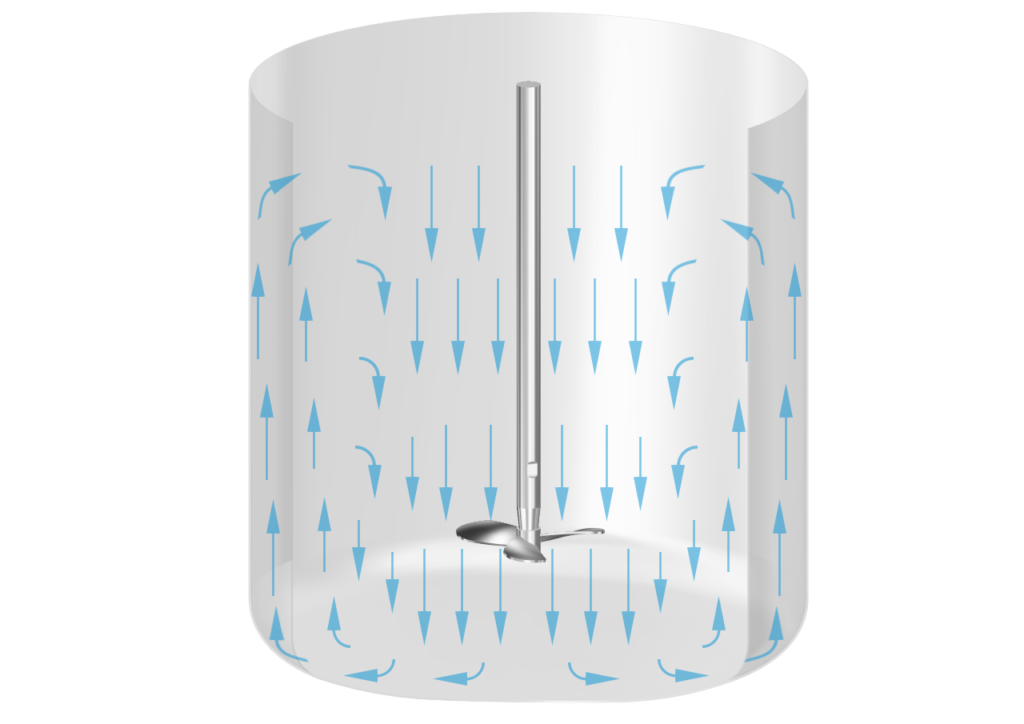

When mixing immiscible liquids, circulation will not be sufficient to homogenise the ingredients. The mixing mobile must allow shearing to disperse one phase into another. This operation is an emulsion, a process used to manufacture cosmetic creams, toothpaste, balms, and sauces in the food industry.

Radial flow turbines are ideal for emulsions, as well as rotor-stators.

How to choose the right tools for a liquid/solid mixture?

Requirements vary according to the characteristics of the particles:

- Soluble powders need circulation to dissolve the particles in the liquid.

- Non-soluble powders:

- Need circulation to suspend the powders in the medium (pigments, for example)

- Or need a shearing effect to disperse the particles. For example, in gel manufacture, the powders used are insoluble, but they change during dispersion. They will change appearance and gel on contact with the aqueous phase.

Axial flow propellers generate circulation.

Radial flow turbines generate more shear to favour the dispersion and transformation of the particles.

How to choose the right tools for a viscous / slurry mixture?

The viscous mixing process is more complex to implement. Industries must add several processes to obtain an optimal result: homogenisation, dispersion, emulsification. In this case, a single mixing mobile is not enough. The Trimix triple agitation mobile integrates an emulsifier for agitation at the bottom of the tank, three-bladed propellers on three levels in the tank’s centre, and a scraper. This mobile allows making a liquid moisturising cream (13% fatty phase) or a thicker body balm (23% fatty phase).

Slurry products (ointment type) need shearing and circulation. Planetary mixers are perfectly adapted for these types of products thanks to the double satellite agitation system (tool revolution in the tank + tool rotation on itself).

And for a liquid/solid/gas mixture

After obtaining the emulsion, air can be incorporated to get a foaming aspect, a lighter and airier product. The circulation movement allows the air integration, and the shearing action reduces the air bubbles’ size. The Ultimix industrial planetary mixer is recommended for this type of mixing.

Agitation mobiles can be classified according to the level of viscosity of the products to be mixed.

In summary: the criteria to retain to choose the mixing mobile

The choice of agitation depends on:

- The type of flow to favour for mixing (axial, radial flow)

- The mechanical effects to generate (circulation, shear, etc.).

- Process parameters: rotation speed, circulation rate, mixing time, etc.

- Functional criteria: the type of mobile, its cleanability, and its retention rate.

- Economic criteria: the final objective is to obtain the best performance for the product’s manufacture.

Would you like to know more about choosing a mixing unit?

Watch the replay of our webinar « The Key Criteria for a Successful Mixing Process » (45 min)

Make an appointment with an expert of our team to get process advices or to learn more about VMI mixing solutions.