The emulsifying process is well-known among skin care and cosmetic manufacturers. It is used in many applications and is the key to obtaining a creamy texture and an easy-to-apply product. But mastering the emulsification process can be challenging. It is indeed a complex process which impacts many characteristics of the product such as its texture, aspect, conservation and the effectiveness of the active ingredients. The process, and particularly the mixing part, plays a key role in obtaining a successful, stable emulsion.

What is an emulsion?

An emulsion is a visually homogeneous mixture obtained from two non-miscible liquids. The most common examples of non-miscible liquids are oil and water. During the mixing, the liquid will disperse into fine droplets.

An emulsion is composed of two phases:

- An aqueous phase, of one or more aqueous elements (water, distilled water, hydrolats… )

- A fatty phase, made of one or more oils (vegetable oils, vegetable butters, wax…)

To enable dispersion and, particularly, homogeneity of the drops, the emulsification process requires a very high level of shearing coming from the mixing tool.

Emulsion types

First, emulsions can be classified according to their complexity:

- Simple emulsions, composed of only two phases (an aqueous phase and a fatty phase)

- Multiple emulsions, which can be composed of several aqueous or fatty phases (generally two aqueous phases and one fatty phase or vice versa)

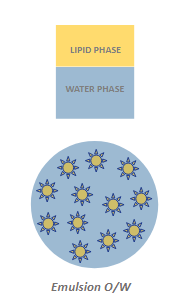

In cosmetics and pharmaceuticals, you can also identify two types of emulsion according to the distribution of phases:

Direct emulsion, also called “oil in water” emulsion (O/W). This is the classic emulsion in which the fatty phase is dispersed into the aqueous phase.

Invert emulsion, also called “water in oil” emulsion (W/O). This is an emulsion in which the aqueous phase is dispersed into the fatty phase.

Direct emulsion is the most commonly used, but an invert emulsion is usually preferable when using active ingredients. They will be dissolved in water before making the emulsion, which will preserve their properties.

Emulsions for cosmetic and pharmaceutical products

Many health or cosmetic applications require an emulsion:

- Milks: face, body, moisturizing…

- Skin care creams and balms, repairing, anti-aging, moisturizing for the body or the hands

- Make-up: mascara, foundation

- Hair care: conditioner, masks

In addition to the constituents from the two phases, many other components can be added during the production and mixing process:

- Emulsifiers, which help stabilize the emulsion. The type of emulsifier will impact the texture of the final product. Emulsifiers can be chemical or natural. The emulsifier will help preserve the homogeneity of the emulsion and prevent droplets from clumping and the phases from separating.

- Active ingredients that give the finished product extra properties, like moisturizing, mattifying, soothing, and anti-aging, among others.

Emulsification: which tool to make an emulsion?

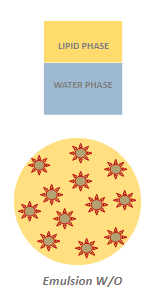

The tool of choice for making an emulsion is a radial flow tool such as a deflocculator or a rotor-stator. The deflocculator is used to make simple emulsions.

For complex emulsions that require a higher shear level, the R/S is more suitable. This tool is the “standard” method for making emulsions with a high-volume fraction of the dispersed phase. It consists of a central moving part – the rotor (impeller or blades) and an external fixed part – the stator, which can have different opening sizes. The air gap between the rotor and the stator plays an important role in the shearing process as the liquid passes between the rotor and the stator during mixing.

Shearing during an emulsion actually includes 2 steps:

- Dispersion, i.e., the mixing between the two phases to obtain drops of 100µm

- Homogenization, which is the reduction of these drops into droplets of 10 µm or less

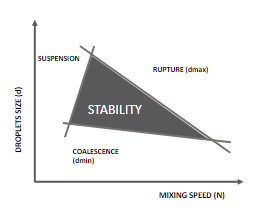

The size of the droplets depends on the mixing parameters (speed/time) as well as the type/geometry of the R/S. Also, the shearing power is increased by increasing the speed or reducing the air gap between the rotor and the stator. Then, the diameter of the drops will be reduced when passing through the rotor-stator.

This tool has a very high shearing power Np=2-6 and a very low flow efficiency Nq=0.5.

- Nq= Pumping number, this is the dimensionless expression of the pumping rate of the agitator.

- Np= Power number. It is the expression of the power consumed

Several types of emulsion can be identified, depending on the size of the droplets obtained:

- Coarse emulsions – 10 to 102µm – macroemulsions

- Fine emulsions – 1 to 0.1 mini emulsions

- Micro-emulsions 0.1 to 0.01

Impact of mixing parameters and ingredients on an emulsion and on the final product

Texture: The texture will be affected by the mixture (droplet size) and the percentage of emulsifier in the preparation. This will impact the viscosity of the mixture, which can vary from milk to thick cream, to mousse.

Color/aspect: The aspect of the emulsion varies according to the size of the droplets. A microemulsion will have a rather transparent aspect while a coarse emulsion will have a milky white aspect.

Adaptation on the skin: The choice of fatty substances and the type of emulsion (W/O or O/W) will affect the skin’s receptivity to the product and depth of penetration. This will enable the creation of products that either enter quickly into the skin or, on the other hand, rich products that form a protective balm.

Factors affecting the stability of emulsions

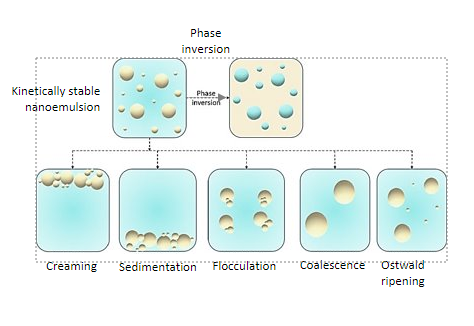

Emulsions are by nature unstable solutions. The goal if you want to make a good emulsion is to ensure its stability. Indeed, a stable emulsion will remain homogenous. Some phenomena related to the instability of an emulsion can lead to temporary alterations (the emulsion can be restored by stirring again) while other so-called destructive phenomena, will lead to phase shift.

There are several emulsion destabilization mechanisms:

- Creaming/sedimentation: when a phase stagnates at the surface of the emulsion or at the bottom of the container used. This will depend on the density of the phases and the type of emulsion (O/W or W/O). These phenomena do not lead to the destruction of the emulsion, and it can be restored by mixing again. To prevent this, the viscosity of the continuous phase must be increased.

- Flocculation: the droplets will aggregate together and form clusters. This phenomenon can be avoided by improving the repulsion phenomenon between the droplets, either by increasing the viscosity of the dispersing phase or by adding emulsifiers.

- Coalescence: This phenomenon is close to flocculation, the difference being that the droplets obtained will come closer together and merge again, which leads to a phase break. The two phases separate, and the emulsion is broken.

A successful emulsion is therefore a stable emulsion that meets the desired characteristics of the final product in terms of texture, color and appearance.

How to ensure emulsion stability

The stability of the emulsion is essentially related to the size of the drops of the dispersed phase, their surface tension and their distribution in the dispersing phase.

Emulsion stability is defined by three conditions:

- No demixing (phase change),

- No chemical reaction,

- No microbiological reaction.

To obtain a stable emulsion, you need:

- An aqueous phase and a fatty phase with a good distribution

- Homogeneous droplets with small diameter

- A dispersing phase with high viscosity

- The use of emulsifiers:

- Thickeners to prevent phase displacement (creaming or sedimentation)

- Surfactants, to improve repulsion between droplets

Some good mixing practices for a successful emulsion

In addition to all these elements, here are some best practices that will help you to make the right choices during your emulsification process:

- Choose the right mixing tool: The tool must be adapted to the complexity of the emulsion. A R/S is necessary for complex emulsions. On the other hand, for manufacturing a simple emulsion, a deflocculator is suitable.

- Adapt the tool geometry to the viscosity of the product: For a thick emulsion, an open stator is recommended.

- Select the right mixing parameters: Mixing equipment that can reach higher speeds if you use a R/S. The deflocculator can be used at lower speeds. It is also necessary to choose the right emulsification time: usually around 15min but you must adapt it according to your parameters and ingredients.

The key to a successful emulsion is to understand the different elements that have an impact on its creation in order to control the process. Using the right mixing tool, as well as a mixer capable of reaching a very high mixing speed will allow you to obtain droplet sizes suitable for a stable emulsion. Consistency of mixing equipment from the laboratory range to large scale production will also be an asset if you want to realize your formulations at bench scale during product development and then extrapolate them easily to large scale production. This is also valid for a process as complex as emulsion. Reproducibility of process parameters is possible thanks to the consistency of technologies and rotor stators between the different ranges.

All you have to do now is select your ingredients to create a product that meets your customers’ expectations.

If you need support, VMI can help you design your products, test formulations and validate the mixing and manufacturing process on your site or in our test laboratory.