Developing new skincare or beauty product must be achieved over increasingly shorter times, for more and more frequent marketing, in response to consumer demand for ever more diversified, personalized and efficient products.

The key points and difficulties of industrial transposition

For each new development or new formulation of cosmetic products, the transition from the laboratory to industrial production is essential. Industrial transposition must integrate process parameters as far upstream as possible. The choice of these parameters, which partly depends on the mixer chosen, must be made very early on from the formulation.

In the laboratory, the challenge is to achieve the desired product and produce it on an larger scale. This scale-up work is even more complicated as it involves different parameters. Therefore, from a laboratory mixer, it is a question of extrapolating the process to produce greater capacity. Controlling the performance of all the operations is also at stake.

What similarity to choose when extrapolating?

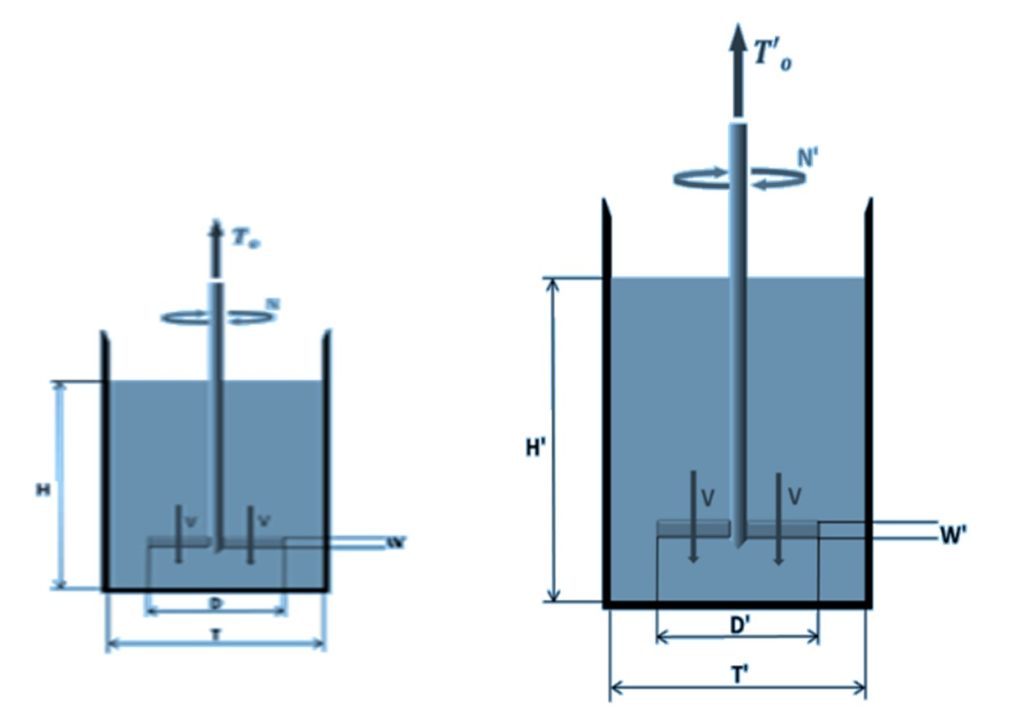

Successful scale-ups key points are the invariant parameters or the principle of similarity and a homothety integrating two or three manufacturing capacities (bench/pilot/industry). This principle of similarity can be of different orders.

A constant dimensional ratio: the geometric similarity

The geometric similarity will apply a homothety on the tools and the tank, and more precisely on their size. All the geometric dimensions between the two scales have the same relationship, called K or scale factor. The tool geometry obtains the ratio K. If this invariant number is above 20, it can be considered unreliable extrapolation similarity and reliable if it is less than 10.

A constant speed ratio: the cinematic similarity

The cinematic similarity consists of extrapolating the rotating tool’s peripheral speeds and can be used when speed is the significant parameter to be considered in the process:

- for shearing needs,

- dispersion,

- emulsification processes.

The peripheral speed or Vp results from the following formula: Vp (m / s) = πND, where N is the speed of rotation of the tool, and D its diameter. The peripheral speed is expressed here in meters per second. We will then vary N1 to N2 and D1 to D2. The homothetic rule will not be the same for these last two parameters, since the tool increases in size, it will then be necessary to slow down its rotation speed to maintain the same peripheral speed Vp.

A constant forces ratio: the dynamic similarity

Finally, other dynamic similarities must be considered, such as the forces between any point on two scales: pressure in the tank, friction, or inertia.

The invariant or ratio results from the recirculation rate or the power density, which is an essential criterion in the homogenization process.

Essential elements to remember for successful transposition

Process and equipment knowledge

Therefore, it is essential in the laboratory to choose the right ‘process’ operating conditions of its formulation. For example, making a mixture with an emulsifier whose rotation speed is 20,000 rpm is undoubtedly advantageous for saving time in the laboratory. Still, it does not make sense if the formulated product is produced on a larger scale.

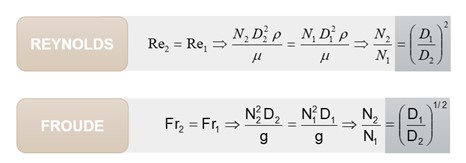

Choice of similarity

Depending on the process, it is necessary to choose the most relevant similarity typology. The incompatibility of specific parameters illustrates this choice, such as the dimensionless Reynolds and Froude numbers. The Reynolds number characterizes the flow of fluids, on which viscosity depends. From this number, it is possible to deduce a turbine diameter to be used (D1 to D2). This same ratio will then be different if calculated from the Froude number, which characterizes the cinematic energy of a fluid relative to its gravitational energy:

Scaling up is always a compromise between the different parameters involved. It is essential to understand them well, whether it is a question of process or equipment parameters or the calculated similarity principle.

Our company VMI, a leader in mixing solutions, works with the biggest names in world cosmetics. We bring our expertise to manufacturers wishing to conduct their industrial transposition efficiently. From bench to pilot to turnkey mixing solutions, the design of our wide range of mixers facilitates the transition from laboratory to the upper scale. Our Process Development Center covers all cosmetic mixing processes. Measurement, control, and evaluation of incoming materials and tested products are achieved in our analysis room. Our customers can try a technology, train in mixing, optimize their process with VMI technologists and equipment in place.

Want to know more about industrial scale-up?

Watch the replay of our webinar « The Key Points for a Successful Industrial Scale-up » (45 min).

Speakers:

- Nesrin Hesso, R&D and Process Engineer at VMI

- Franck Henriot, Sales Director at VMI